Maintenance Management System

The maintenance management system supports user-built server and Ali cloud server provided by Taibo to operate in two ways.

No need for dedicated maintenance,get started quickly.

Features include:

Equipment parts management,equipment history file management,maintenance work order closed-loop management,daily maintenance management,inspection management,contractor cross-merchant collaborative management,data analysis, etc.

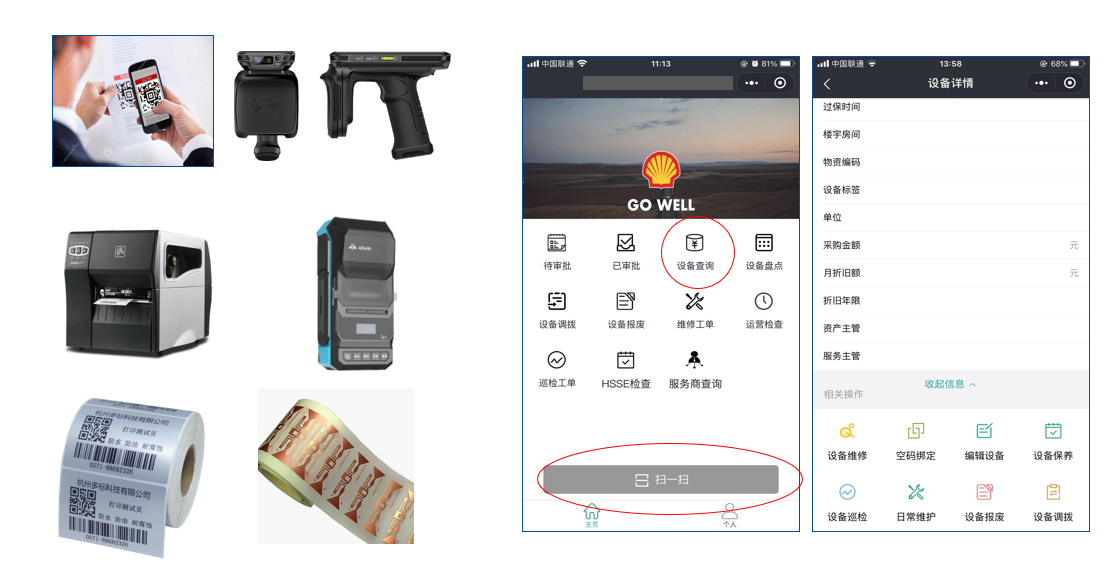

Using QR code /RFID as access channel to achieve equipment assets:

Identity authentication,GPS and latitude and longitude binding,information query,code scan report repair,inspection report,information change,etc.

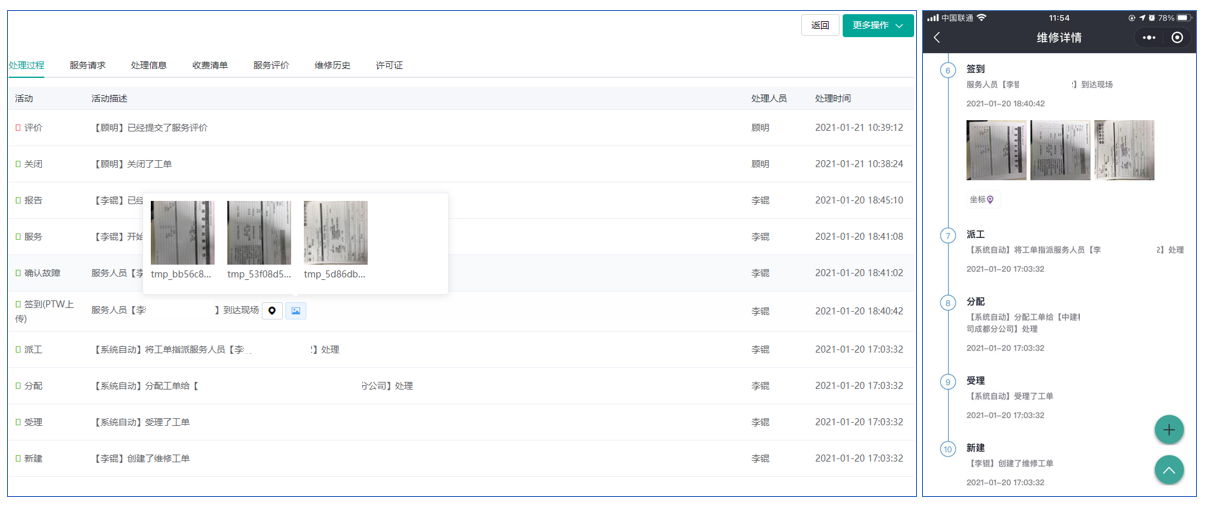

Terminal to terminal for whole-process management of cross-enterprise service collaboration.

After a device fault is reported,the system supports automatic (defining rules) or manual repair,two ways to dispatch work orders to internal teams or external suppliers.

After receiving the work order,the maintenance personnel will perform the maintenance on site,fill in the maintenance report after completion and the fault initiator will close and uate the work order.

Digital inspection: eliminate hidden dangers in the bud and put them into place.

Seting the inspection work plan for devices or device group,combines the inspection execution main body and automatically generates inspection work order.

Determine the time (season, month, week, and day) and which devices need to be inspected.

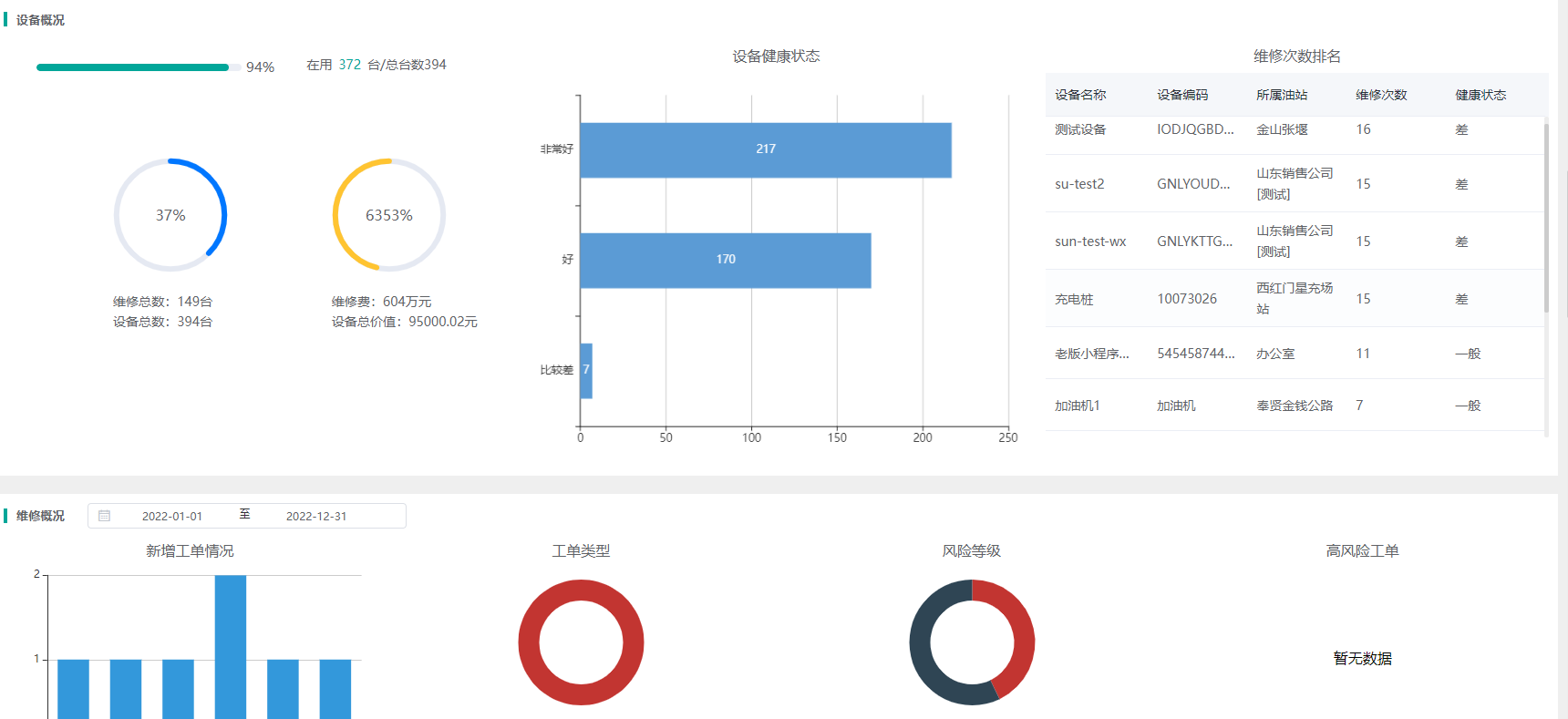

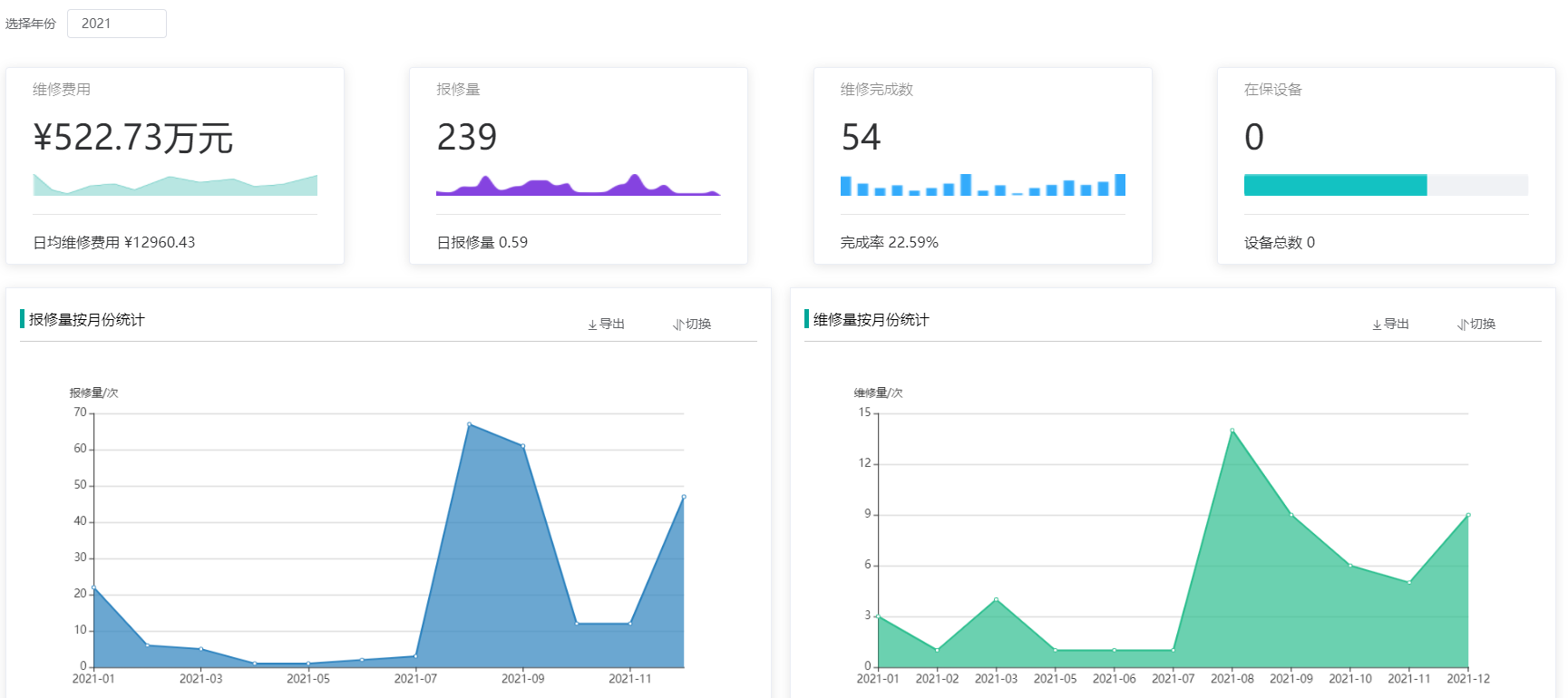

Multi-dimensional data statistics and analysis include:

Maintenance statistics,cost statistics,satisfaction statistics,downtime,repair,repeat maintenance,materials & service items,etc.

Different convenient management experience.

Maintenance statistics:

Failure statistics:

Cost statistics: